About Us

Vision

To become a global leader in providing innovative technology to ensure the highest levels of safety in the oil and gas infrastructure industry.

Mission

To provide cutting-edge nano-coating sensing technology for instant detection of Hydrocarbon leakages in pipelines to prevent accidents and reduce the negative impact on the environment.

Problems To Solve

-

Ageing Infrastructure

Many pipelines in the country are over 50 years old. Require significant investment to maintain and upgrade. As pipelines age, they become more vulnerable to leaks, ruptures, and other safety hazards. Pose a risk to both the environment and public safety. Costly and time-consuming process for pipeline operators. Can result in significant revenue losses, and the cost of repairs and upgrades can be substantial.

-

Limitations of the Existing Technologies

False alarms are common in several leak detection techniques used in Canada's oil and gas supply pipeline industry. For example, acoustic emission, NPW (Negative Pressure Wave), and DSP (Digital Signal Processing) techniques are susceptible to generating false alarms.

-

High Costs

The cost of implementing and maintaining leak detection systems is a major concern for pipeline operators, particularly smaller companies with limited resources. The cost of installing and maintaining leak detection systems can vary widely depending on the technology and the size of the pipeline network. Some systems require regular maintenance to ensure reliable and accurate operation. Some systems can be a complex process that requires specialized expertise and equipment (ex. microwave reflectometry). This can add to the overall cost of implementing and maintaining the system.

Our Solution

Nano-coating Sensing Technology for Instant Detection of Hydrocarbon Leakages

We provide a hydrocarbon leak detection system that enables operators to locate leaks quickly.

Pipeline leaks are detected early, preventing costly losses and environmental damages.

Detecting leaks in the Oil/Gas industry has never been easier with our ultra-sensitive sensors.

PipeGuard Solutions can be applied to a wide range of applications, such as refineries, tank farms, oil terminals, and pumping stations.

Our solution utilizes advanced analytics and algorithms to analyze data collected by the sensors to minimize incidences of false alarms.

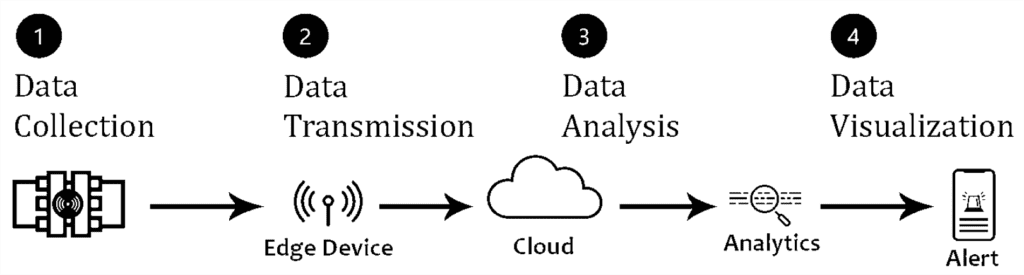

How It Works

Advantages

Instant

Detection

Instant detection of leaks can help pipeline operators take prompt action to prevent environmental damage and mitigate financial losses in the oil and gas pipeline industry.

Highly Resistant to Harsh

Weather Conditions

The optimized curing process used in the manufacture of the leak detection technology makes it highly resistant to harsh weather conditions, ensuring reliable operation in various environmental conditions.

Rapid Location

of Leaks

The rapid location of leaks using this technology will help save cost and time by allowing operators to quickly identify the source of the leak and take prompt action to mitigate its impact.

Detection of

Tiny Leaks

The technology is capable of detecting even the tiniest leaks, allowing operators to catch potential problems early on before they become more significant and costly to repair.

Close-to-Perfect

Reversibility

The technology has close-to-perfect reversibility, meaning that it can recover to its original size and conductivity once the hydrocarbon causing the leak is removed, making it a cost-effective and sustainable solution.

Independent of Pressure or

Flow Balance

The nano-coating sensor technology is designed to be independent of pressure or flow balance, making it suitable for reliable operation in various pipeline conditions.

Product Packages

Product-as-a-Service

To provide its pipeline leak detection service to pipeline operators.

License-Out

It’s technology to both domestic and international oil and gas infrastructure companies.

Strategic Partnership

With energy infrastructure companies to act as its partners to offer its leakage detection sensors.

Testimonials

Meet The Team

Thi Hoang Dung Do

Chief Executive Officer

Ms. Thi Hoang Dung Do is a highly reliable and focused individual with 13 years of experience in atmospheric and climate science. She has worked as a Volunteer, Contestant Guide, Project Manager’s Assistant, Officer, and Owner. As Chief Executive Officer of PipeGuard Solutions, Ms. Thi Hoang Dung Do will utilize her prior experience in project management, environmental protection, and real estate to satisfy both short- and long-term company objectives and capitalize on any new business opportunities. Her extensive leadership skills ensure the success of PipeGuard Solutions in the Canadian market.

Thu Huyen Le

Chief Business Development Officer

Mrs. Thu Huyen Le is a highly motivated professional with 17 years of experience in investment banking, institutional finance, and project management. She has worked as a Deputy of the Project Department, Investment Banking Administration Staff, Senior Account Manager, Freelancer, and Director of District 7 Branch. As Chief Business Development Officer of PipeGuard Solutions, Mrs. Thu Huyen Le will be an instrumental resource in the company’s growth initiatives, especially in their calculated move into the Canadian market.

Nguyen Phuong Trang Thuong

Chief Technology Officer

Mrs. Nguyen Phuong Trang Thuong is a petroleum engineer with 16 years of experience in various geology and petroleum roles. She has worked as a Research Assistant, Geoscientist, and Owner. As Chief Technology Officer of PipeGuard Solutions, Mrs. Nguyen Phuong Trang Thuong will continuously improve processes, implement new technologies, and foster the growth and development of the company, which will ensure her ability to drive business success, optimize operations, and deliver exceptional results.